Katalysatorenfertigung

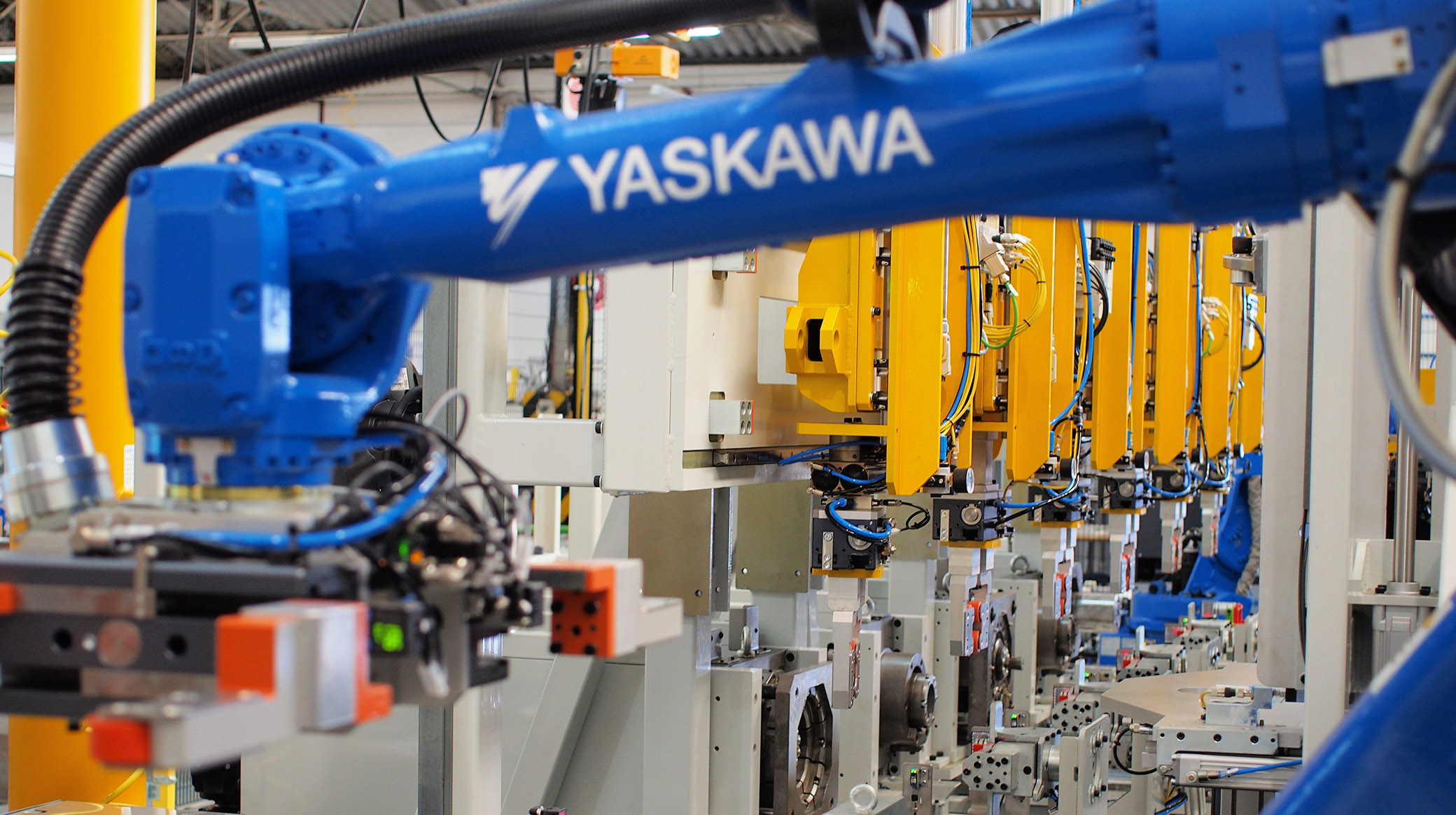

Das Größenabhängige – Canningverfahren ist immer mehr in den Fokus der Automobilindustrie gerückt. OEM`s benötigen die bestmöglichen Herstellungsverfahren um die Emissionswerte der verschiedenen Märkte / Länder zu erreichen. Jendamark hat eine große Auswahl an flexibelen, automatisierten Montagesystemen um den Kunden eine bestmögliche Auswahl zu bieten

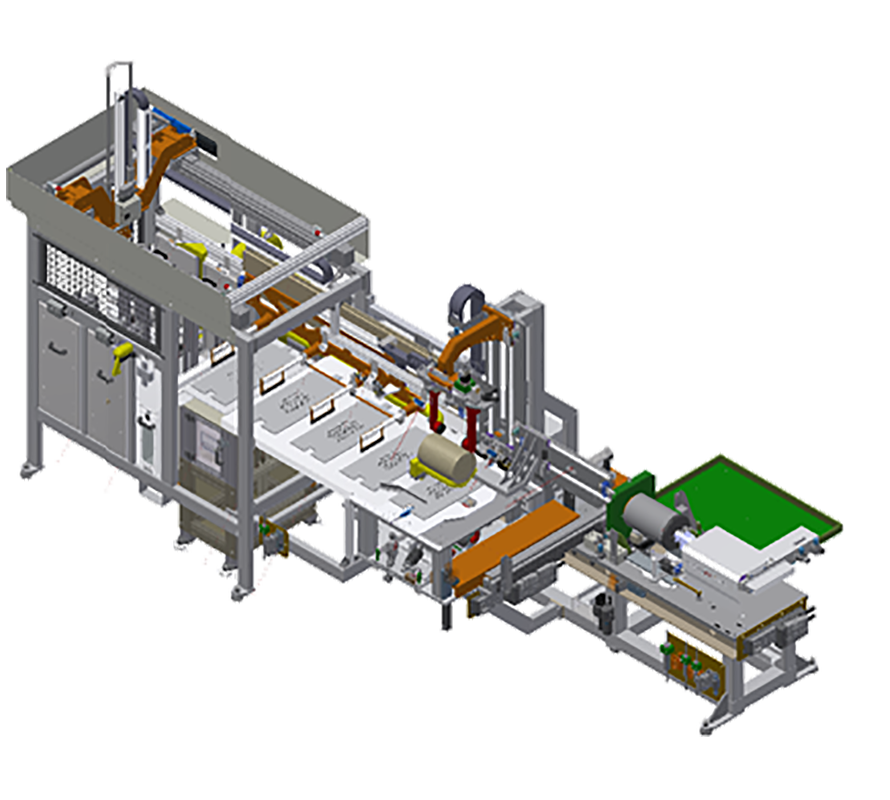

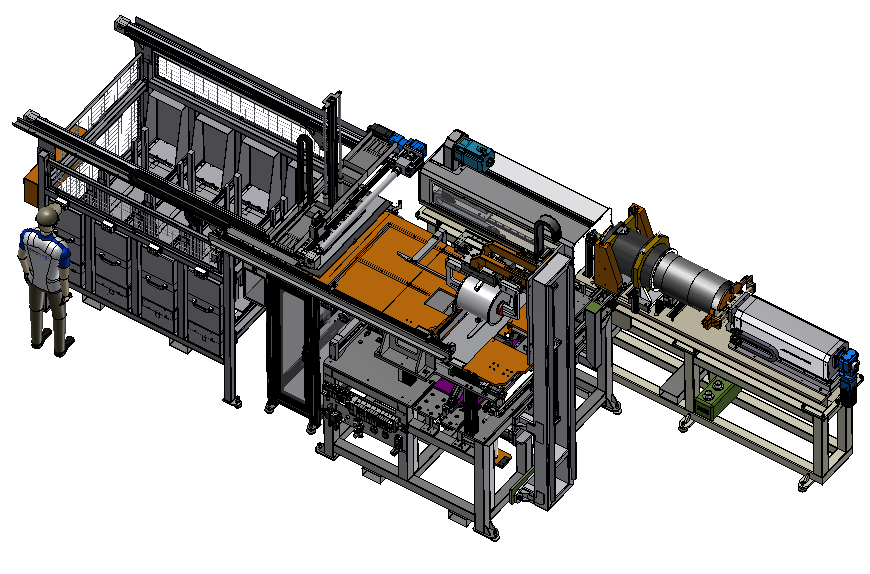

Canninglinien

Standard-Canning-Module

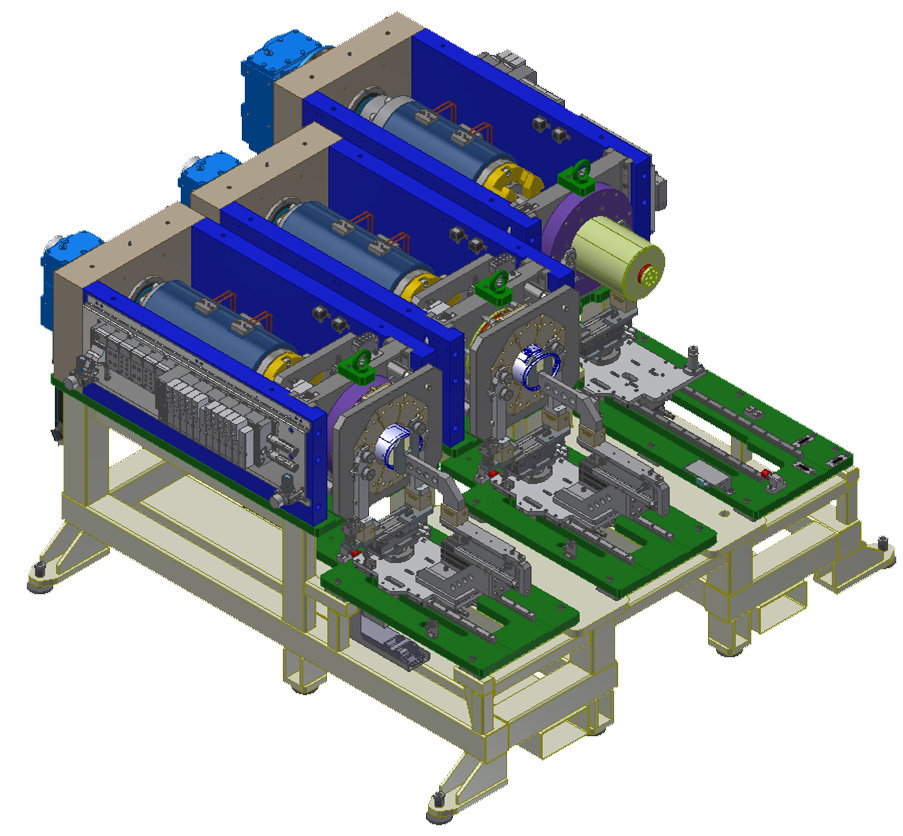

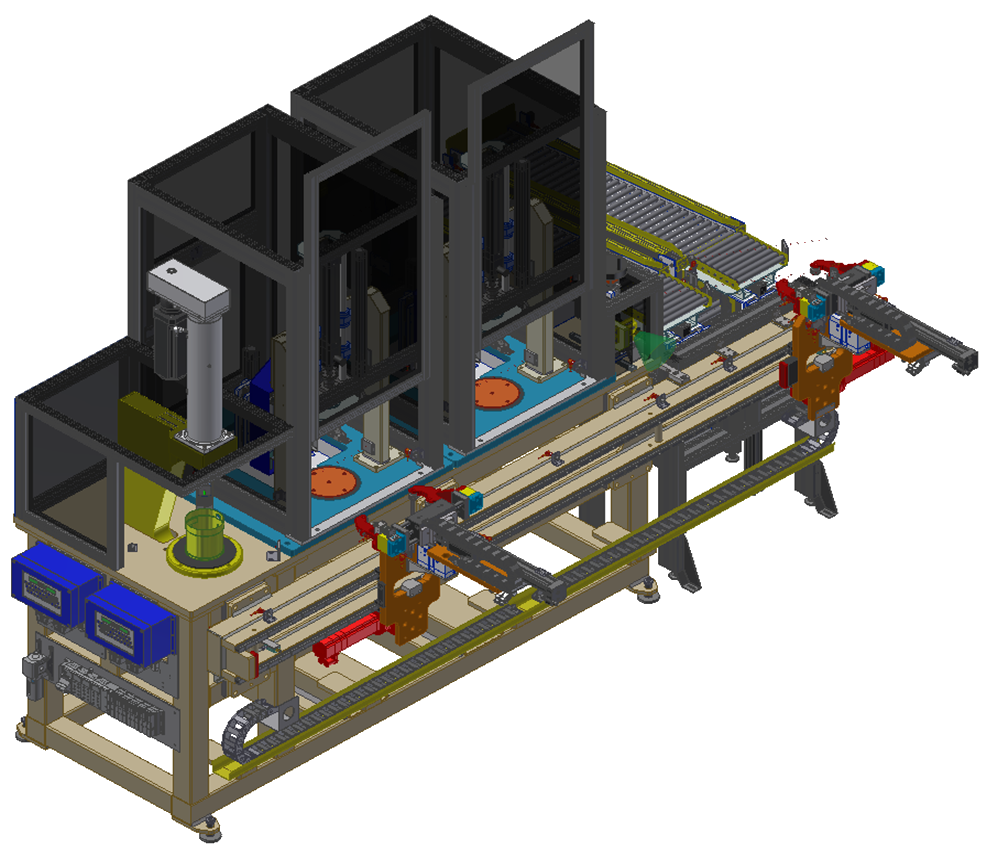

Die Palette der Standard-Canningmodule von Jendamark kann auf verschiedene Arten in einer Produktionslinie konfiguriert werden, um eine individuelle Systemösung zu schaffen, die den genauen Spezifikationen des Kunden entspricht.

Die standardisierten Canningmaschinen von Jendamark können problemlos zu manuellen, halbautomatischen oder vollautomatischen Anlagen zusammengestellt werden. Egal, ob der Prozess GBD oder nicht GBD-gesteuert ist, Post-Sizing (soft stuff) oder Pre-Sizing (hard stuff), Jendamark hat eine Lösung. Unsere Maschinen haben sich in der Industrie bewährt und richten sich sowohl an Personen- als auch Nutzfahrzeugserien.

Economy-Canning-Module

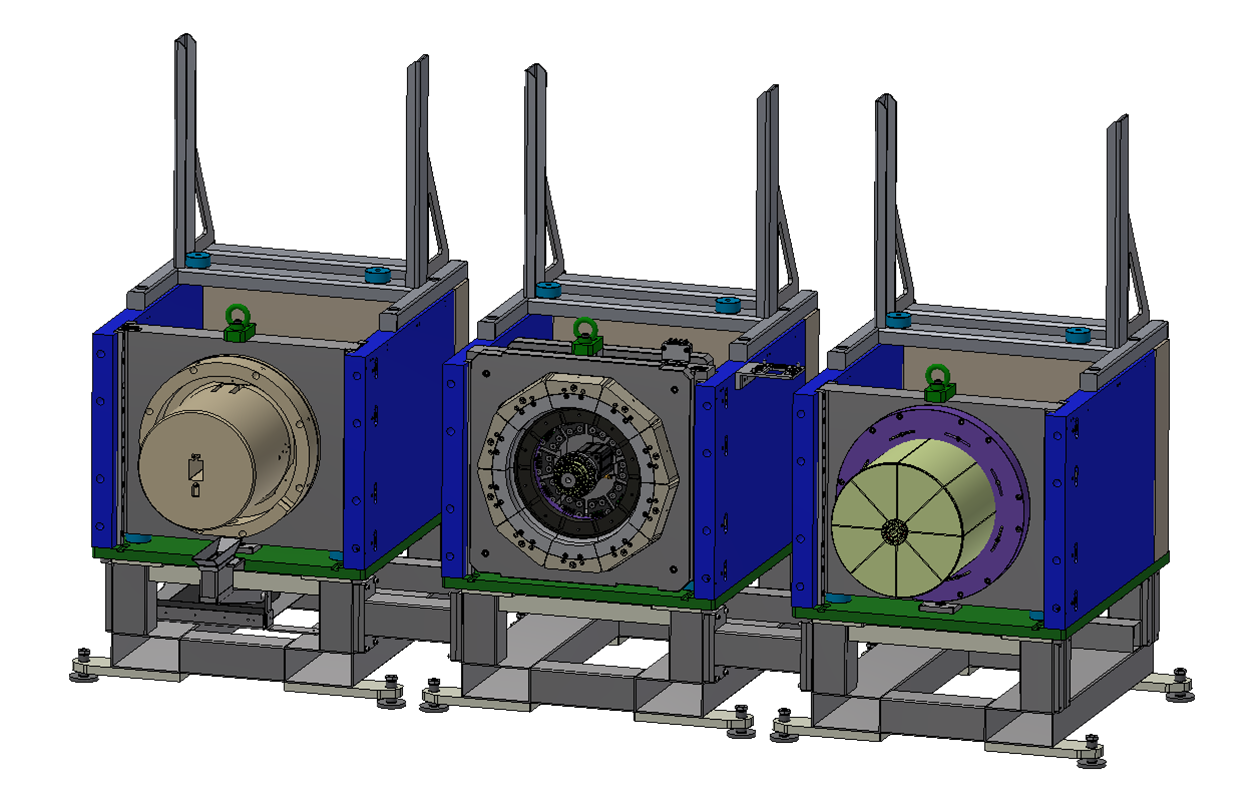

Für Kunden, die eine vereinfachte, kostengünstige Lösung suchen, bietet die EconoLinie von Jendamark eine allgemeine Option, wenn weniger Flexibilität erforderlich ist. Mehrere Module werden in einer Standardkonfiguration kombiniert und auf einer einzigen Grundplatte montiert.

Zu den Maschinenangeboten in dieser Produktpalette zählen der Econo Shrinker und die neue Econo-Messmaschine.

Facilities

Mattenwiegen

Auto Stuffing Press

|

|

|

Passenger Vehicle

|

Commercial Vehicle

|

Wickeln

Auto Stuffing Press

|

|

|

Passenger Vehicle

|

Commercial Vehicle

|

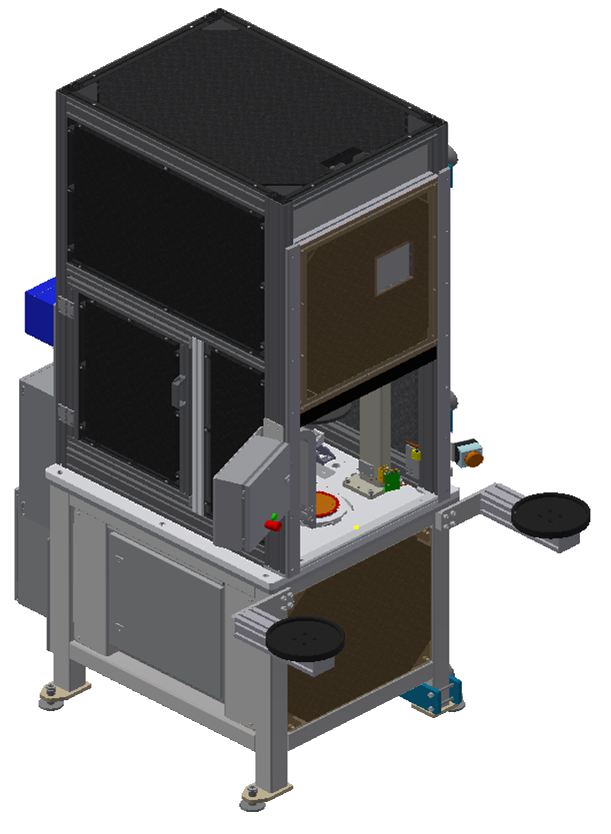

Messmaschine Substrat

Measuring Machine

|

|

|

Measuring Machine (Manual)

|

Measuring Machine (Automatic)

|

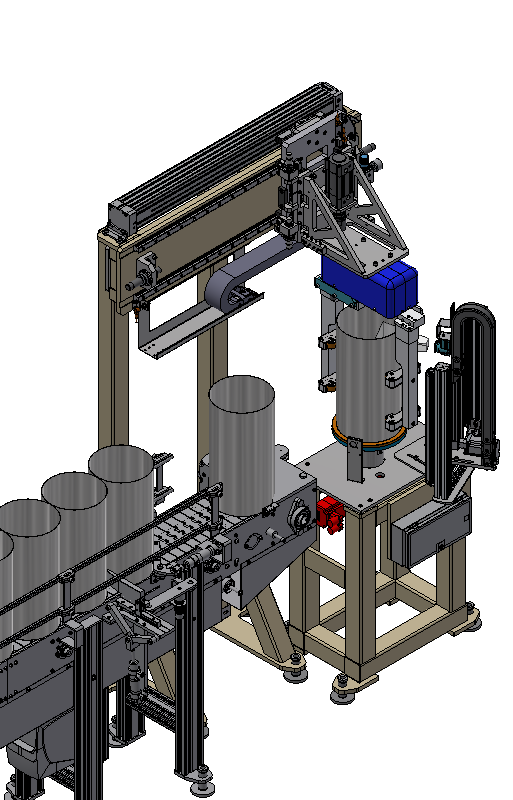

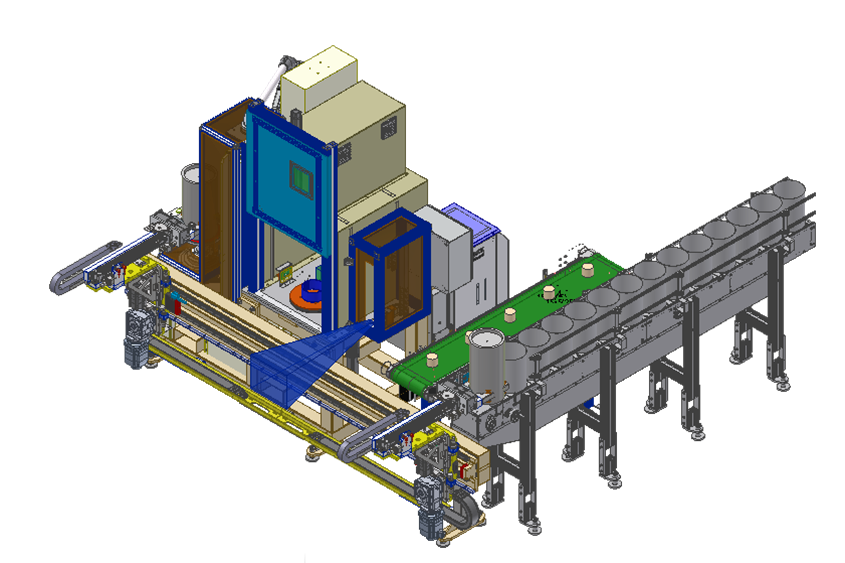

Rohr ausrichten

Can Orientation Machine

|

|

Can Orientation Machine (Automatic Cells)

|

Einschieben

Auto Stuffing Press

|

|

|

Passenger Vehicle

|

Commercial Vehicle

|

Endenbearbeitung

Forming Machines

|

|

|

Passenger Vehicle

Machine Types Include:

|

Commercial Vehicle

Machine Types Include:

|

|

|

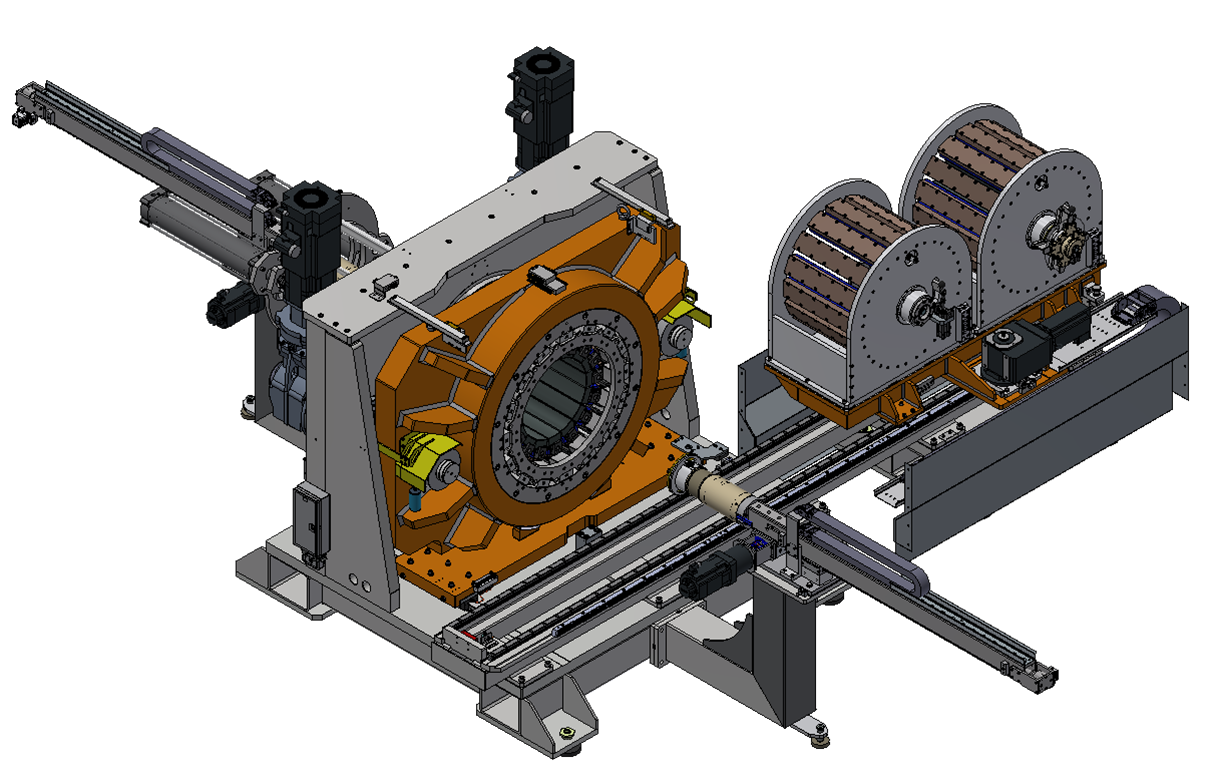

Double Shrinking Machine

|

Aufweiten

Forming Machines

|

|

|

Passenger Vehicle

Machine Types Include:

|

Commercial Vehicle

Machine Types Include:

|

|

|

Double Shrinking Machine

|

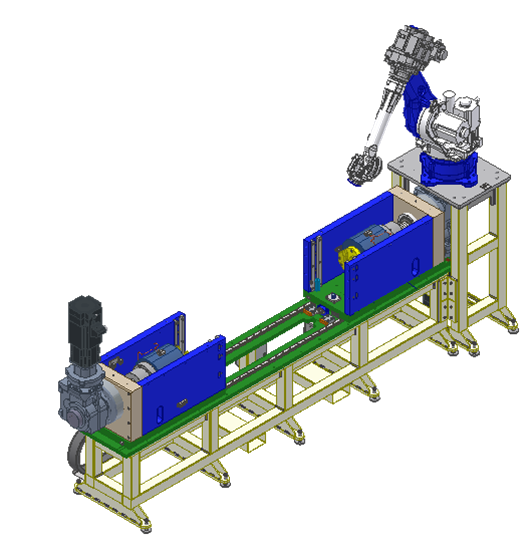

Shrinken / Einziehen

Shrinking Machine

|

|

|

|

|

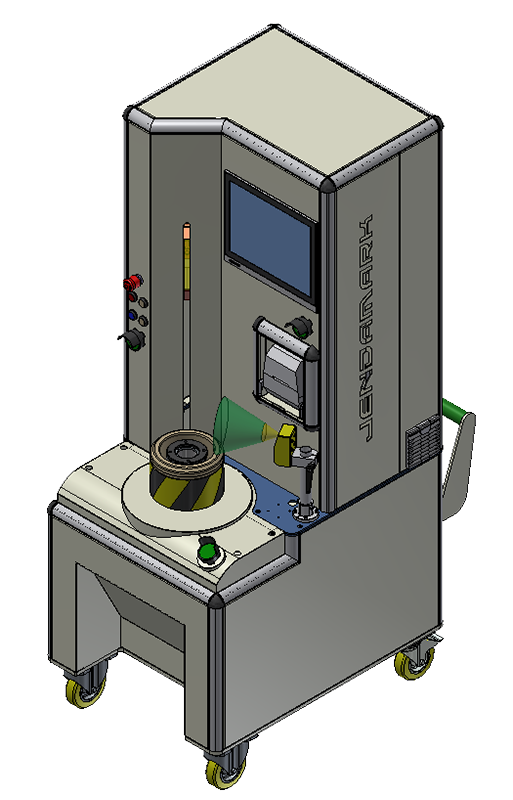

GBD Messung

Measuring Machines

|

|

|

Measuring Machine (Manual)

|

Measuring Machine (Automatic)

|

Markieren

Marking Machines

|

|

|

Passenger Vehicle

|

Passenger Vehicle

|

Commercial Vehicle

|

|

Endmontage

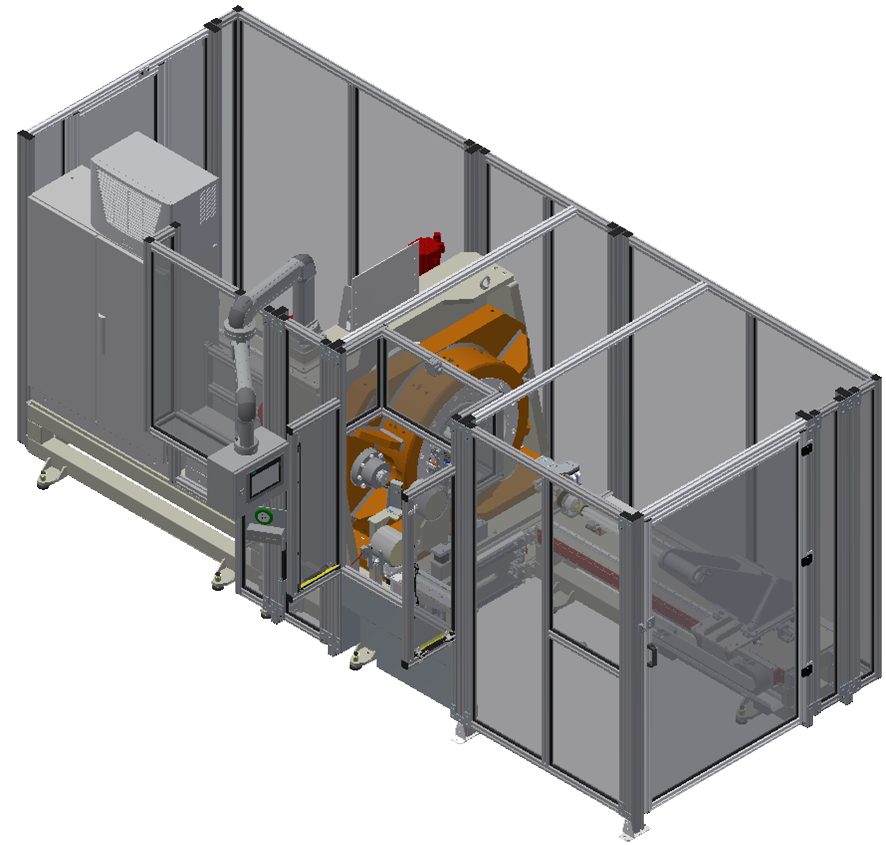

Jendamark bietet auch End-of-Line-Montagesysteme an, bei denen die Produkte, die von den Canninglinien kommen, mit anderen Elementen zu einer größeren Baugruppe kombiniert werden, die zum Einbau in das Fahrzeug bereit ist.

Die Endmontage umfasst Aspekte wie Prüfen, Markieren, Messen und Dichtheitsprüfung, um sicherzustellen, dass das fertige Produkt den höchsten Qualitätsstandards entspricht.