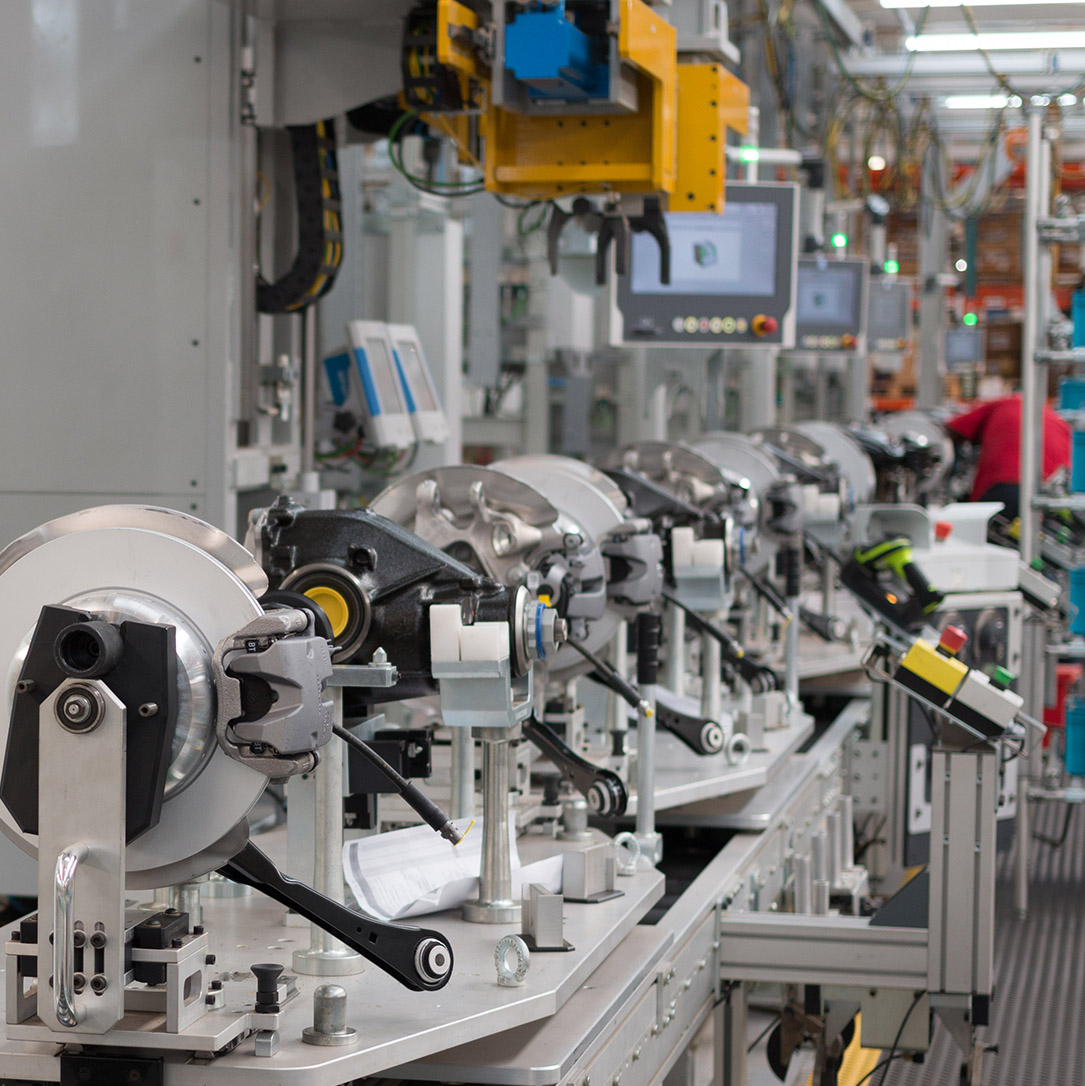

Powertrain

Industrie 4.0

Katalysatorenfertigung

Jendamark als Arbeitgeber

Eine Anstellung bei Jendamark eröffnet Ihnen weltweite Karrierechancen.

Wenn Sie interessiert sind in Ingenieurwissenschaften, Programmierung, Konstruktion, Entwicklung freuen wir uns darauf Sie in unserem internationalen Unternehmen willkommen zu heißen.

Aus- / Weiterbildung

Jendamark bietet offizielle KUKA Roboterschulungen in Pretoria, Südafrika an. Die Seminare sind modular aufgebaut und ermöglichen eine schrittweise Qualifizierung auf Basis zertifizierter Qualitätsstandards. Bei Jendamark verfügen alle Ausbilder über eine praktische Ausbildung sowie langjährige Erfahrung und sind in der Unterrichtsmethodik ausgebildet.

News & Events

Industry 4.0: Virtual reality

Jendamark’s virtual reality room allows designers and customers to explore the possibilities of a new production line in three-dimensional reality via an interactive, computergenerated experience. The introduction of virtual reality (VR) has had tangible, real world...

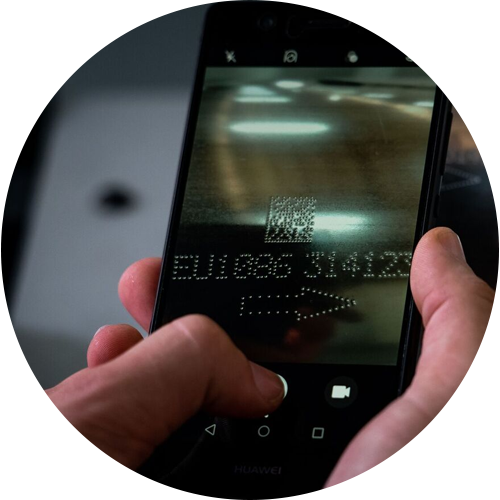

Industry 4.0: Internet of Things

The Internet of Things (IoT) describes a network of machines, devices and other items that have built-in connectivity, electronics, software or sensors that allow them to share data and improve efficiency for humans interacting with them. While the idea of a “smart...

Industry 4.0: Augmented reality

Augmented reality (AR), as the name suggests, uses technology to augment or add to a user’s experience by superimposing computer-generated images, text and sounds over a real-world environment. AR creates an immersive and interactive experience for the user, which...