More commonly known as 3D printing, additive manufacturing is gaining momentum in the quest for lightweight parts and minimum material waste.

Instead of machining away metal to fashion a part, additive manufacturing builds it up from scratch, using only the material needed.

“The other big advantage is the idea of topology optimisation – redesigning a part to make it lighter in weight,” says Yanesh Naidoo.

This, Naidoo says, allows for complex lattice-like design, not unlike the bone structure of birds, which is strong but could reduce weight by up to 70%.

“This is a big goal for the automotive industry because it would make cars easier to run on smaller engines. Our assembly machines would in turn require less powerful motors, which would increase their longevity and reduce costs.”

While metal 3D industrial printers remain prohibitively expensive, Jendamark is exploring using industrial robots with MIG weld guns to build up parts.

“The structural integrity still needs to be tested but if it proves successful, a designer could print raw materials overnight and put them into the machine shop the next day,” says Naidoo, adding that it could shortcut the material purchasing process by weeks.

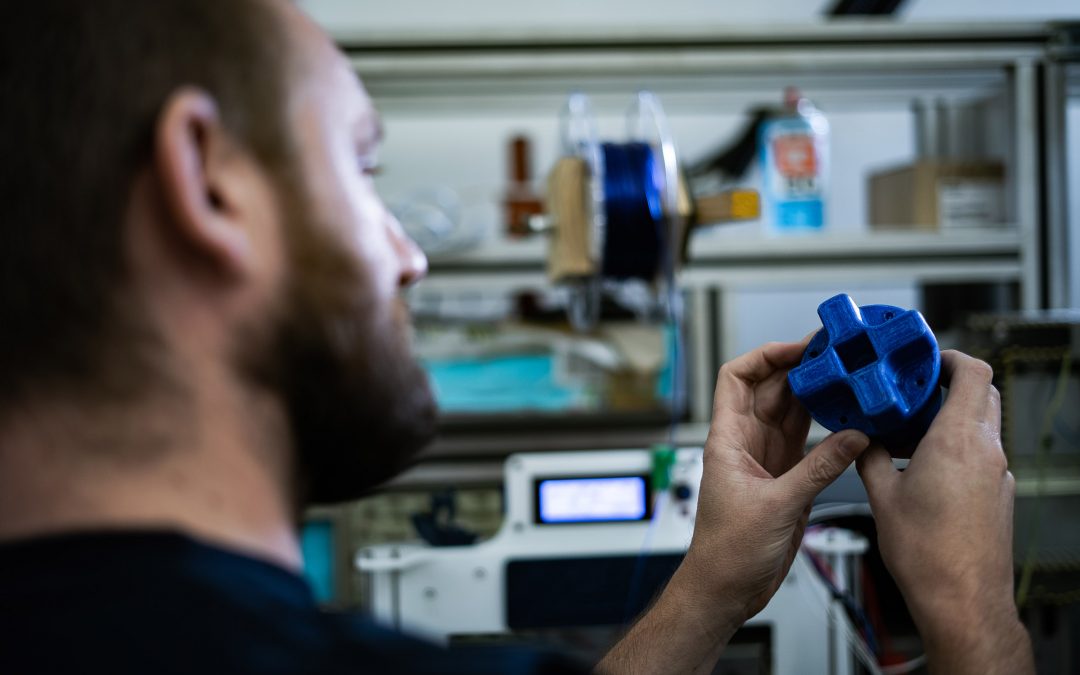

Jendamark’s 3D printer is used to print plastic components, which are especially useful in the development phase, giving designers a feel for the real thing. The initial testing of lines is also done using these.

“Print-on-demand spares for plastic components, such as air vents, are now accepted in the automotive industry worldwide – especially for older model vehicles, where it is no longer cost effective to produce and store large

volumes that may never be used.”